Advanced Assembly

Scale assembly without building everything in-house. We take responsibility for subsystems or complete machines and connect the flow into stable quality, predictable delivery, and shorter lead times—from first prototype to tacted series.

Three key advantages

Capacity that follows the product

From small, complex subsystems with hundreds of parts to the final assembly of complete machines—we scale the setup to your needs. You can outsource the entire chain or a defined segment, always with methods and documentation aligned to your product and SLAs. The outcome is capacity that grows with your project and maintains consistent quality throughout the flow.

Quality built in—nothing left to chance

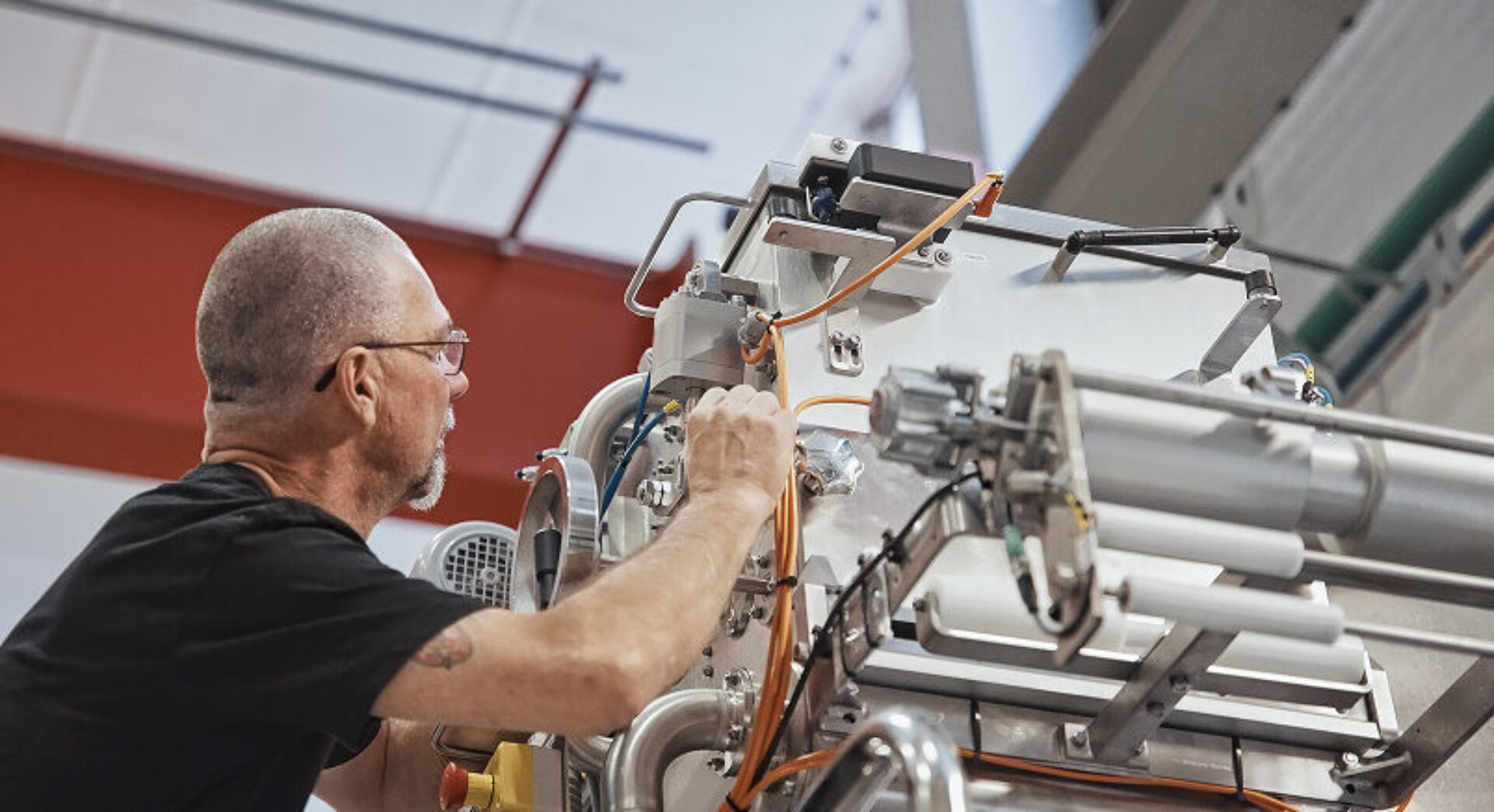

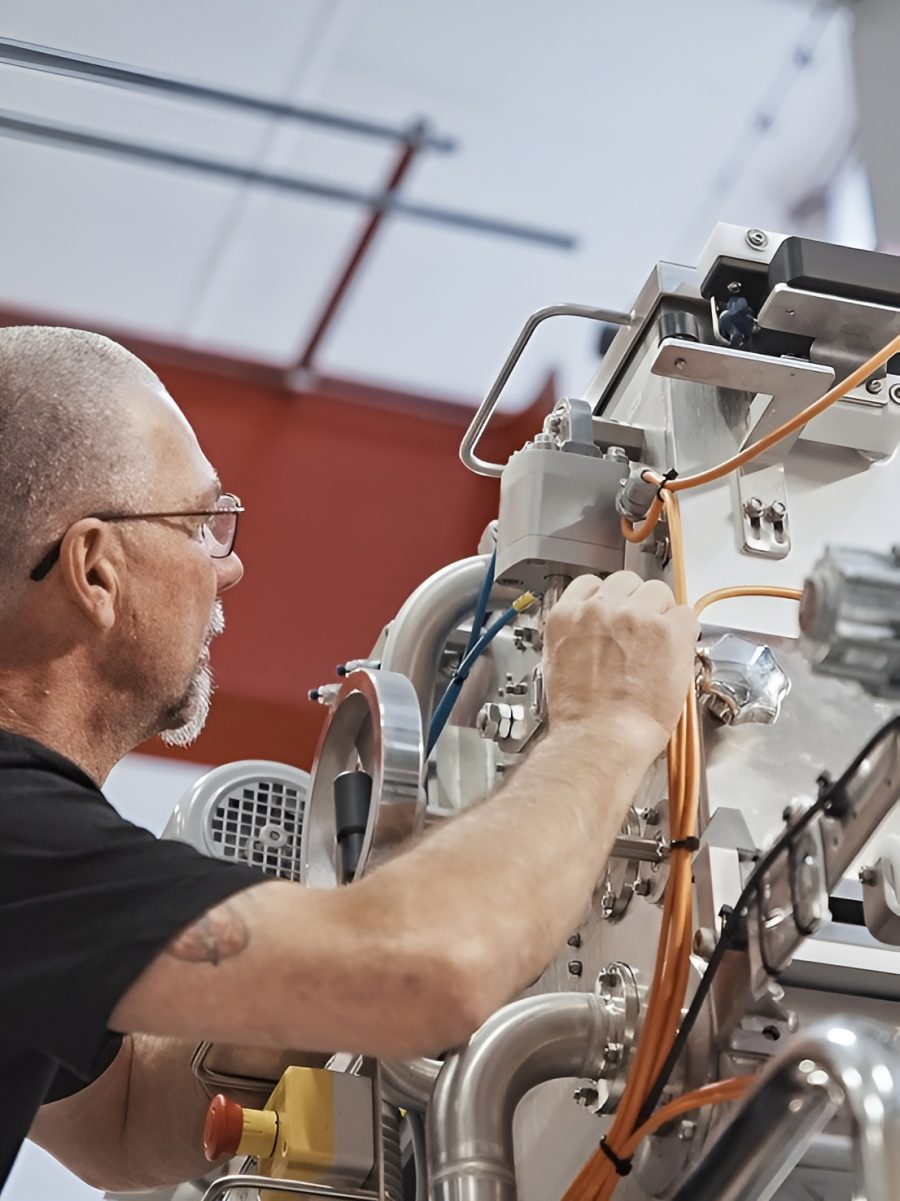

Our assembly technicians work across mechanics, electrics, pneumatics, and hydraulics. It takes about 12 months to become fully autonomous in assembly production—a level that reflects the testing and troubleshooting demands of complex mechanical systems. The result shows in the outcome: on average 0.78 deviations per machine at volumes of around 80 machines per year.

Integrated within Industrial Ecosystems™

Assembly is a strategic node in our industrial ecosystem. Insights from production feed back into manufacturing engineering—and to you—when parts don’t fit or methods can be simplified. This way both product and process improve in the next step, creating continuous learning, shorter lead times, and more robust production over time.

A partnership for business value

Assembly is about more than following a blueprint—it’s about a steady workflow where each step supports the next. At UFAB we treat assembly as the hub connecting material supply, machining, welding, sourcing, and industrialization into something that works in practice. When variation is high and systems are complex, the difference is obvious: the right sequence, tools, and checkpoints stabilize delivery from day one.

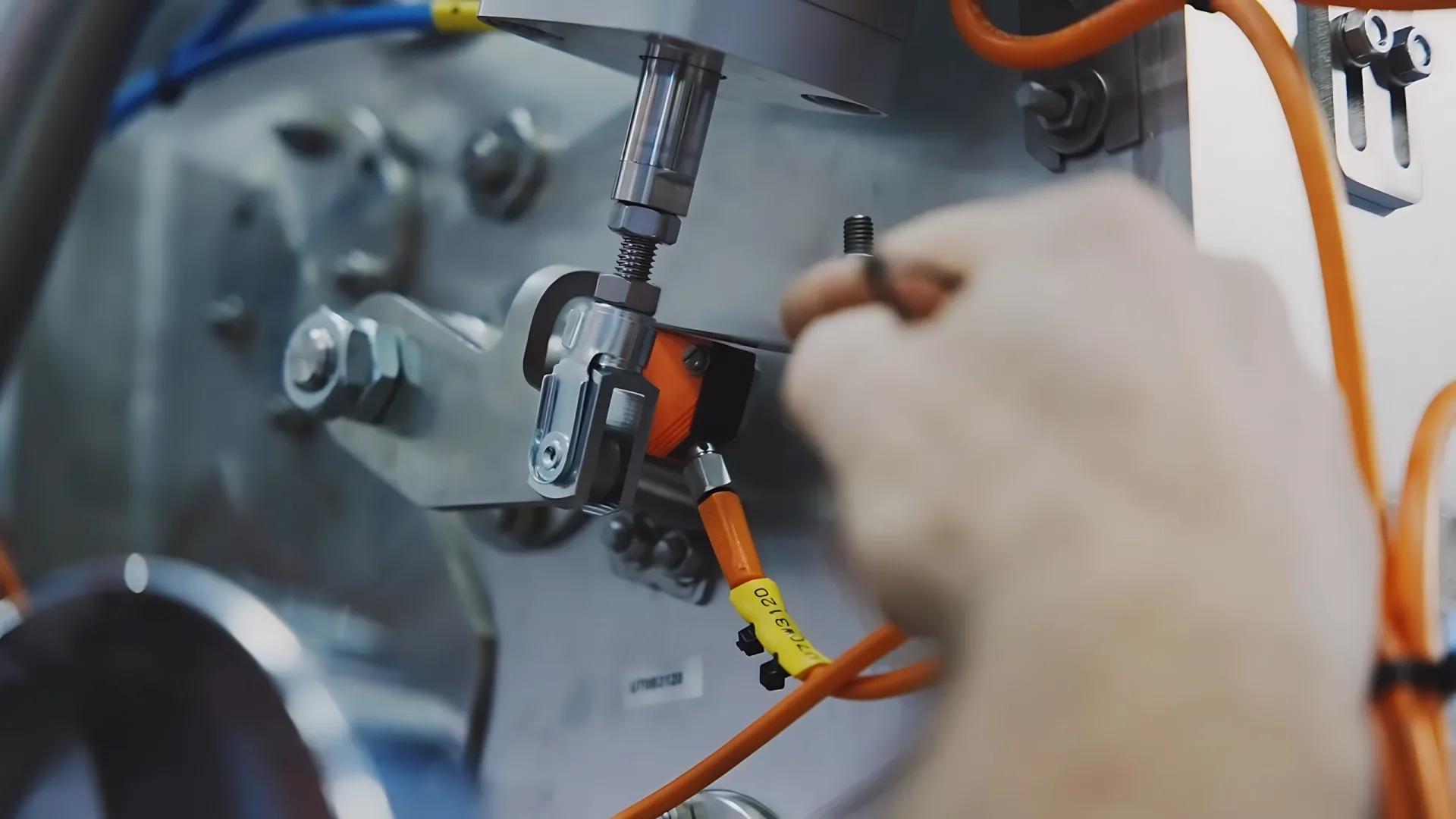

In practical terms, the same System Builder assembles a larger share of the product, taking end-to-end responsibility at the station and following clear methods—from mechanical fits and fixtures to cabling, I/O termination, pneumatic leak checks, and hydraulic pressure tests. Every delivery closes with functional testing, protocols, and full traceability. That level of ownership and documentation reduces rework and makes ramp-up predictable.

When simplification or risk reduction is possible, we shorten the feedback loop: a technician’s observation becomes a change in methods and clearer documentation for the next build—and, when relevant, a concrete improvement proposal to your team. Assembly is not an island but a value-creating node in Industrial Ecosystems™

Contact usTypical deliverables

Mechanical Assembly

• Frames

• Module

• Fixtures

• Fasteners

• Fits

• Linear units

• Bearing systems with ball bearings, roller bearings, needle bearings

Electrical Assembly

• Cabling

• Enclosures

• Sensors

• I/O termination

• Connectors (incl. cable assembly)

• Electric motors

Pneumatics

• Valves

• Tubing/fittings

• Leak checks

• Pressure tests

• Air cylinders

Hydraulics

• Manifolds

• Hoses/fittings

• Leak-tightness

• Pressure tests

Testing & Verification

• Functional tests

• Protocols

• Traceable documentation

• Electrical safety test

• Functional test

• Leak test

• Helium test

• Vacuum test

• Passivation of piping/filling systems

Two ways to better performance

Core Services

Co-Design

Through early involvement, we optimize manufacturability with CAD expertise and in-house prototyping – reducing cost, lead times, and improving efficiency.

Welding

Our certified welders ensure high-precision welding for demanding applications, delivering strength, durability, and quality in every joint.

Machining

From prototypes to large-scale production, we provide high-precision machining with tight tolerances, optimized for efficiency and performance.

Assembly

We handle everything from subassemblies to fully integrated systems, ensuring seamless functionality and quality at every stage.

Sourcing

Leveraging a trusted supplier network, we secure the right materials and components at the right time—ensuring cost-efficiency and reliability.

Industrialization

Transform complex ideas into efficient, scalable production systems—streamlining every step from design to deployment with minimal waste and maximum impact.