Industrial Performance™

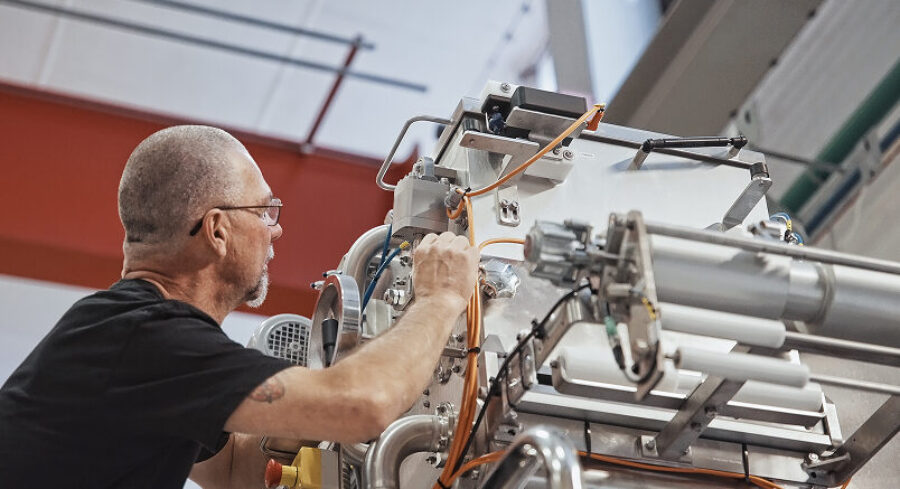

Demands on industry are changing fast. The old ways of working – isolated fixes and silo thinking – are no longer enough. New times call for new playbooks. We call it Industrial Performance™—a new way to achieve more, with less.

How it works

From volume to value

We don’t follow old models based on output alone. Industrial Performance is a mindset shift – from production as a function to production as a capability. From more, to smarter.

Precision without compromise

Speed means nothing without accuracy. We deliver faster without sacrificing precision – because true performance demands reliability in every step.

Efficiency that lasts

We reduce costs and environmental impact without slowing things down. It’s not about isolated fixes, but continuous improvements that deliver real results.

It’s not just about improving parts – it’s about reshaping the logic of modern industry. Industrial Performance builds on five fundamental shifts shaping manufacturing today – helping our customers stay ahead, perform better and unlock long-term value.

Performance

From volume to performance

We’re moving away from volume-driven production. Instead, we measure performance by how resources are used, how quickly we adapt – and how precisely every detail meets the demands of speed, accuracy, and sustainability.

Adaptive

From improvement to optimization

Stepwise improvements are replaced by continuous optimization. With real-time data and AI, flows are fine-tuned constantly. Technology enables it – but it’s people who create direction, focus, and progress.

Resilience

From global chains to robust systems

Resilient production requires more than strength – it demands agility. When global supply chains are disrupted, production must scale, reroute, and continue without losing precision or momentum.

Insights

From instruction to insight

Automation frees up time – but it takes competence to create value. In a skills-driven industry, progress is built on system understanding, pattern recognition, and continuous improvement – not just execution.

Sustainable

From impact to potential

Circularity and resource efficiency are no longer side efforts – they’re core business. Reducing waste and energy use is both a climate action and a competitive edge shaping the industry of tomorrow.

Where margins define momentum

It’s not just about machines, flows, or metrics. It’s about how we work together. Listening. Challenging. That’s how we build systems that perform – and relationships that last even longer. We call it Industrial Performance. Our customers call it peace of mind.

Discover our expertise

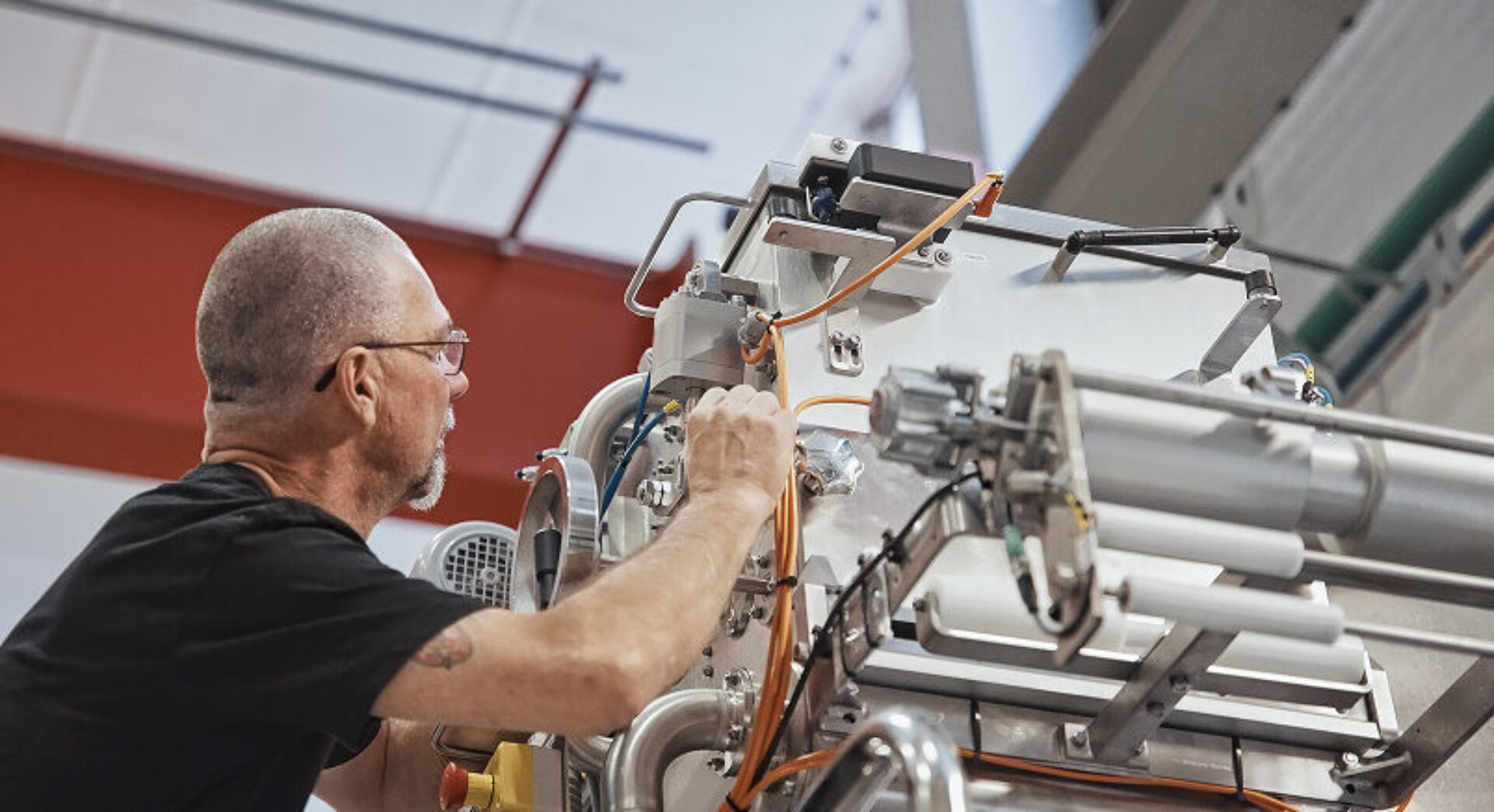

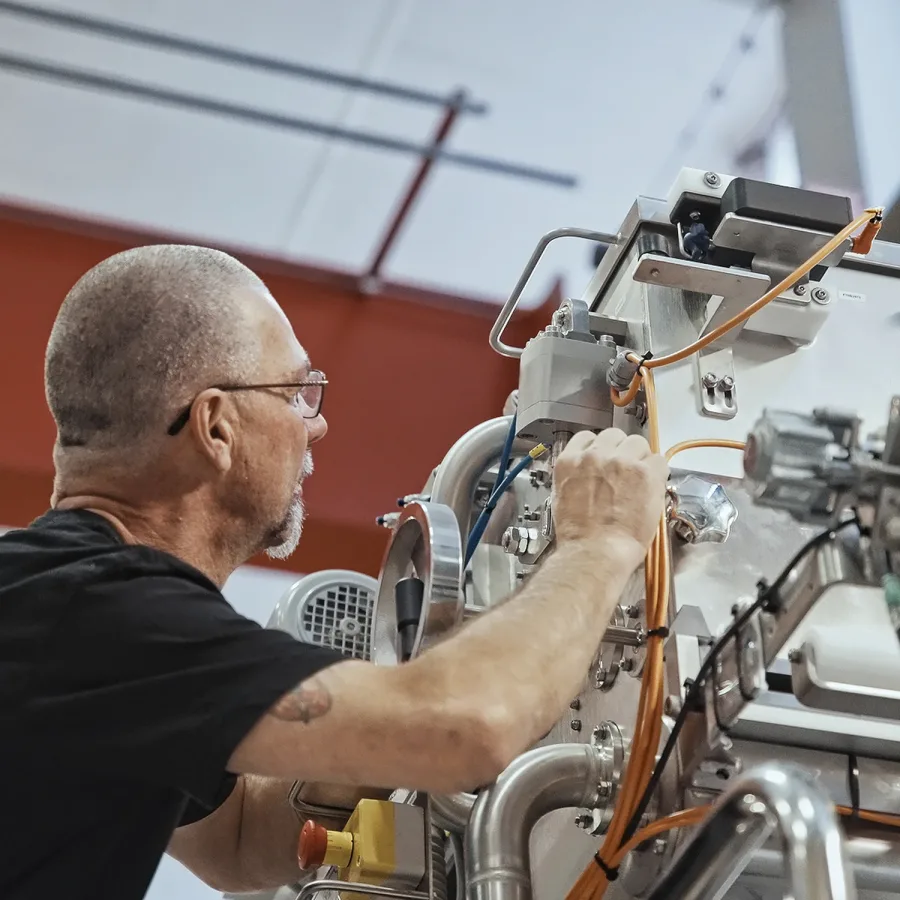

Complete systems

System deliveries and advanced assembly — built for reliability

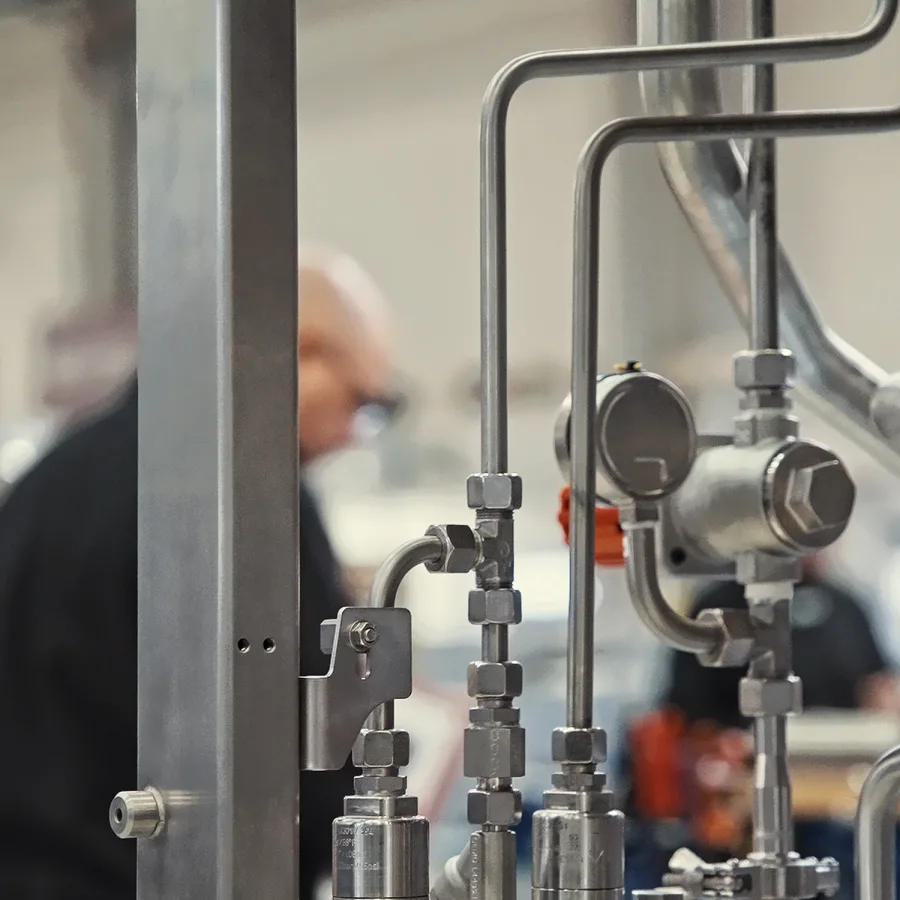

Advanced components

High-performance components and expertly machined parts